Jain HDPE Pipes Jointing Connections

-

NO CHAIN IS STRONGER THAN ITS WEAKEST LINK is a common saying which can also be applied to the piping system joints. The main requirements to be fulfilled are hydraulic tightness as well as structural stability of the system.

For the satisfactory performance of Jain HDPE pipe system, design and installation methods mainly rely on the appropriate choice and properly made connections. An adequate and properly made pipe joint will lead to faster and non-hazardous systems operations.

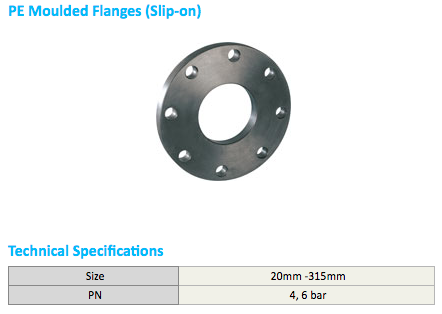

With a view to fulfill the above important aspects of pipeline system as well as to provide the user industry a choice based on application and economy, Jains have developed several types of jointing systems for their range of JAIN HDPE piping systems like – butt fusion, electro-fusion, which are permanent joints and detachable joints such as flanged joints, self restrained sure-loc joints, Quick-Connect® joints and compression joints. The choice of joint required for installing Jain HDPE piping system depends upon requirements based on internal or external pressure, leak tightness, restraint against longitudinal movement, construction and installation requirements as well as application.